SUN-ARC welding electrodes are the leader in quality welding consumables for over 50 years with its current manufacturing plant in Gujarat, India. Original promoters have been associated with SUN-ARC since it’s beginning in 1966.

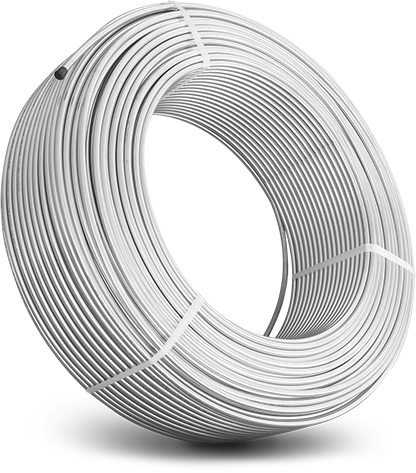

Sun-Arc is one of the leading manufacturers of MIG, SAW and TIG welding wires in India. The company has gained a premier position in the vendor list of leading Automobile Manufacturers / Ancillaries, Engineering lndustry and various railway organizations. The brand name has secured a significant pan-lndia position in terms of quality and performance.

The first factory was set up in Surat, Gujarat with technical collaboration from Welding Electrode Company of United Kingdom. Sun Arc Welding Electrodes Pvt. Ltd. Vadodara, Gujarat purchased the plant, machinery, technical know-how and SUN-ARC brand name in 2020.

Our mission is to be recognized as a major partner in the stainless steel wire industry we choose to produce and to be a preferred supplier to all of our customers.

Stringent quality controls measures are adopted to ensure that welding wires are perfectly manufactured as per lnternational Standards. ISO Quatity Management System has been implemented as a result of which all products are of world-class competence. Continuous efforts in the field of research and development are carried out so as to introduce new welding products and offer better services to all our customers.

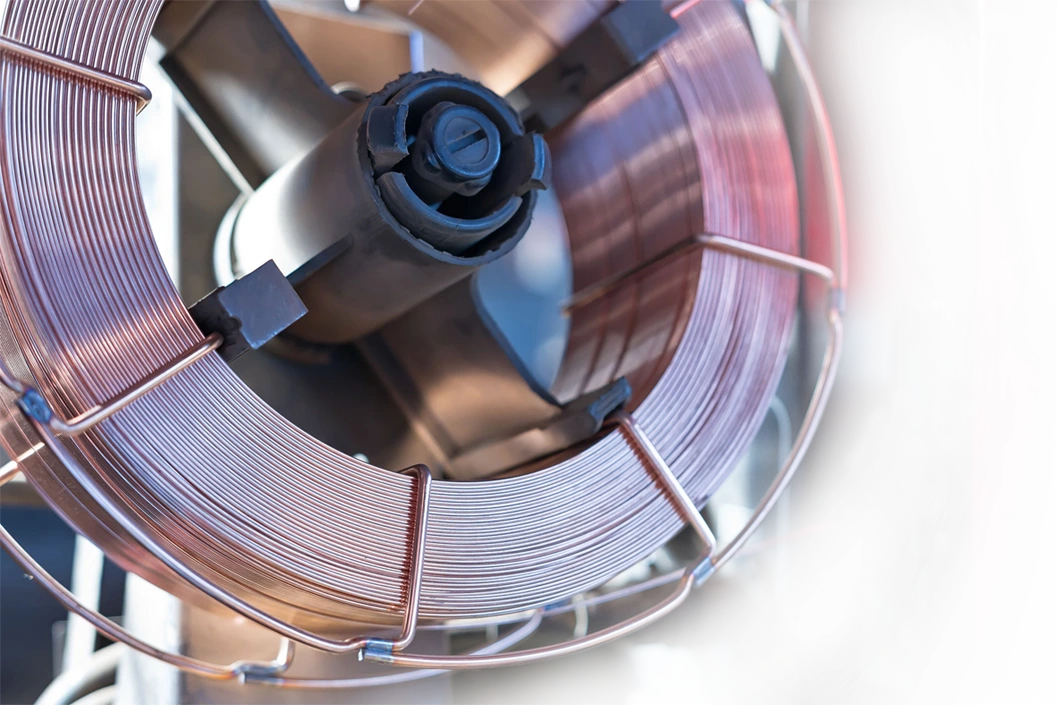

Special Jumbo spools and Drums have been developed for specific applications / SPMs. The Steel Bobbins are supplied as per customer specification and schedules. Regular feedback is recorded and necessary corrective actions are taken in case of any complaints / suggestions received. Emphasis on product & quality upgradation has been a constant endeavor.

Welding Wires are uniformly and carefully copper coated. The coating thickness is maintained at optimum level so that fumes have minimum copper. This is to protect welder's health and environment. Efforts are now focused to produce Copper Free Welding Wires.